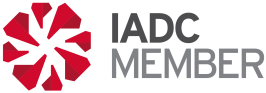

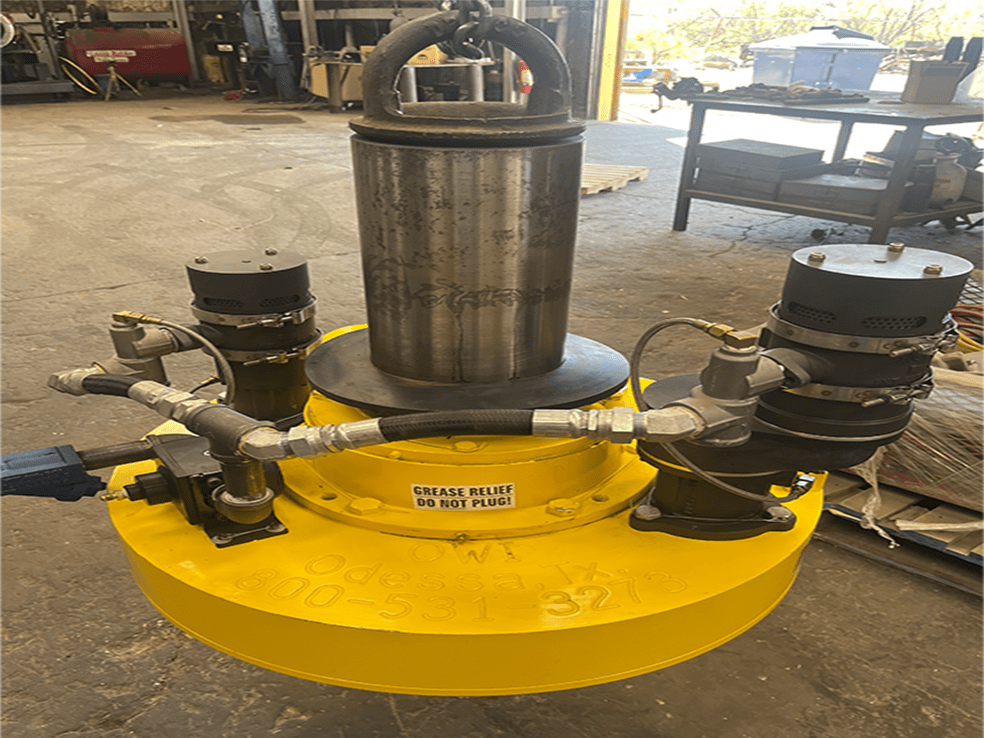

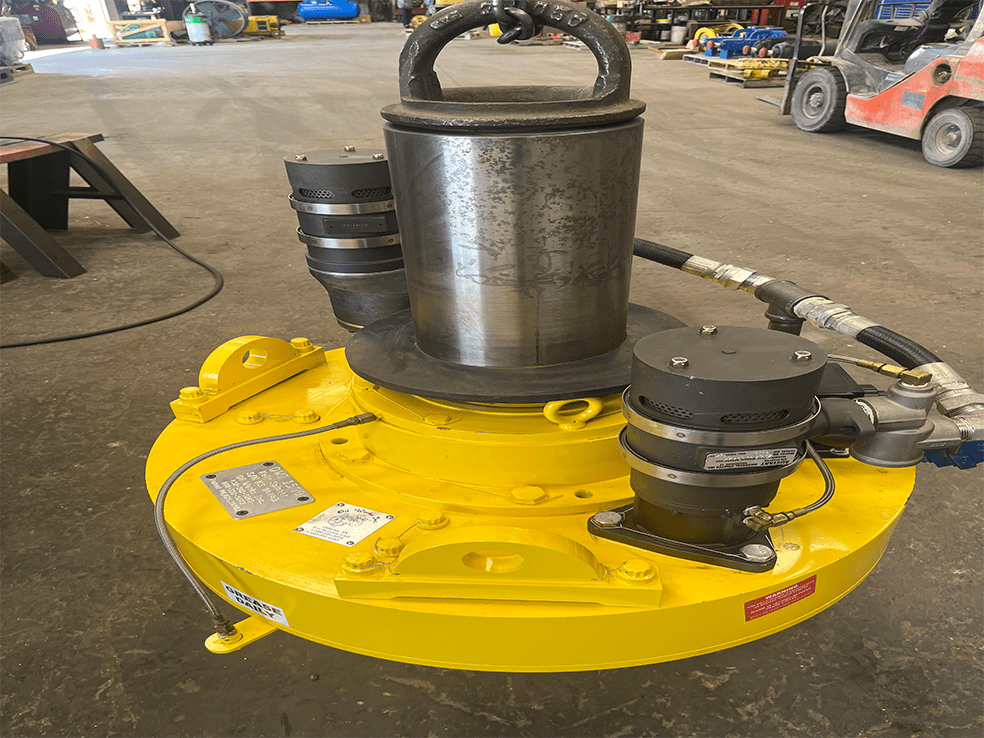

MODEL OWI 1500 KELLY SPINNER

Pneumatic Kelly Spinners currently on the market are single-speed (wide open). They are engaged by opening a valve that can only supply full airflow to the motors on the Kelly Spinner which means they can only be operated at full speed (approximately 150-200 rpm, depending on load) when making up or breaking out pipe.

OPERATIONAL FEATURES

Streamlining Drill Operations with Automated Rotation

The OWI 1500 includes a Pilot Operated Pressure Control Valve & Throttle Control Actuator Valve which gives

the operator full control over the speed range (rpm) of the Kelly Spinner from 1-200 rpm. This is a huge safety

factor in the operation of these units.

Enhancing Safety and Efficiency on the Rig Floor

…has been in the repair and manufacturing business for over 25 years. During this time we have repaired many. Pneumatic Kelly Spinners and in most cases have found the same failures and safety issues. We have addressed this problem and believe our new OWI 1500 Pneumatic Kelly Spinner to be the best on the market. We offer variable speed control, increased torque through its entire rpm range, increased safety, and decreased maintenance..

Built to Last: Durability and Reliability in Challenging Environments

The OWI 1500 utilizes a Turbine motor which will operate efficiently from 1-200 rpm stem speed. The Turbine

motor requires no lubrication and uses only a “Y” strainer to keep large debris out of the motor. The air use for

the OWI 1500 @ 120 psi. is approximately 475 scfm and produces approximately 37 hp and 105 ft-lb torque.

Pneumatic Kelly Spinners currently on the market use a bearing arrangement that includes a tapered cup and

cone in a top bearing carrier and a tapered cup and cone in a bottom bearing carrier. This arrangement allows

the Kelly Spinner Stem to move inside the housing when the pipe is being torqued which results in wear on the

stem and labyrinth plates. This arrangement also allows for excessive bearing clearance and in some cases

premature failure.

OIL WORKS, INC.

Pneumatic Kelly Spinners currently on the market use a Vane-type air motor. This type of motor requires a surge of air to start its rotation and must maintain a certain speed to continue rotating. The air use for these Kelly Spinners @ 120 psi. is approximately 600 scfm and produces approximately 25 hp and 93 ft-lbs torque. The Vane type motor also requires treated air that must go through a lubricator and water filter to clean the air supply before it enters the motors.

BENEFITS & DESIGN FEATURES

Automated Rotation

The OWI 1500 Kelly Spinner automates the process of rotating the Kelly or drill pipe, reducing the need for manual labor on the rig floor. This feature enhances efficiency by expediting the drilling process.

Quick Connection and Disconnection

The OWI 1500 Kelly Spinner facilitates swift connection and disconnection of the Kelly to the top drive or rotary table, minimizing downtime between drilling operations.

Robust Construction

Designed for durability, the OWI 1500 Kelly Spinner is constructed with high-quality materials that can withstand the harsh conditions encountered in offshore and onshore drilling operations.

User-Friendly Interface

The OWI 1500 Kelly Spinner features a user-friendly interface that allows operators to easily monitor and control its operation, enhancing usability and efficiency.